Training in Motion

The use of simulators has become increasingly popular in a variety of les industries–aviation, construction, port management, military, healthcare, and more. Technologies that enable simulation include virtual reality (VR), augmented reality (AR), 4K monitors, motion-based hardware, industry-specific tactile controls, high-definition sound systems, and cutting-edge software. Premium simulators in each industry use many of these technologies together, integrated into a complete training experience. In each scenario, the goal is the same–replicate the real world as closely as possible.

Crane simulators, for example, replicate the operation of real cranes through technology that allows companies to train employees in complex tasks and scenarios without risking their safety and reducing the risk of damage to property and equipment.

One of the most important features for crane simulation training is a true-to-life motion-based system. According to Brad Ball, GlobalSim’s Vice President of Sales and Marketing, “To create a truly immersive training experience, the simulator should replicate the motion that an operator feels in the real equipment.” By replicating the motion that an operator feels in real equipment, the simulator provides a realistic experience that helps trainees be better prepared for real-life scenarios.

“There are a variety of different motion bases available in the market, manufactured by a number of different companies”, says Ball. “Most of the time, the electrical actuators are located under the operator’s seat, and the operator will feel the chair move (or jerk) while practicing on the simulator. At GlobalSim, we prefer a different approach by building a motion base for the entire cabin.” Ball refers to GlobalSim’s proprietary motion base used on the Simulateurs de mission complets, where the motion actuators are located under the entire simulator, not just the operator’s chair. “The realism on a full mission system is much more life-like when the entire simulator moves just as the crane cabin would in real life.”

Uses of Motion-Based Systems in Crane Simulators

The applications for motion-based systems in crane simulators are numerous. The technology can be used to simulate different types of crane operations, such as lifting and lowering heavy objects, maneuvering materials around obstacles, and controlling multiple cranes simultaneously. Student operators practice various scenarios so that they become familiar with how each type of movement should be performed before attempting them on an actual job site. Simulations can help operators adapt quickly when faced with new or unexpected situations at work since they have already experienced similar conditions virtually beforehand.

Motion-based systems also allow users to test out different configurations and settings prior to using them on-site, which helps minimize any potential risks associated with working on unfamiliar equipment. Compared to traditional instruction methods, simulators provide an engaging environment where people can practice their skillset without fear or hesitation due to their low-risk nature.

Degrees of Freedom

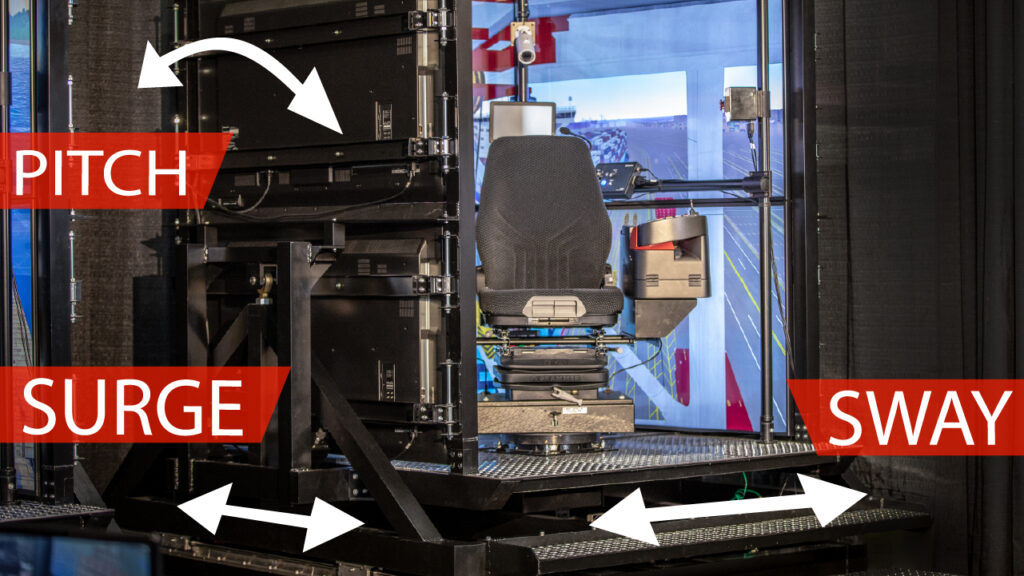

The realistic sensation of GlobalSim’s crane simulators has everything to do with Degrees of Freedom (DOF), a term that refers to the freedom of movement of a rigid body in three-dimensional space. The six Degrees-Of-Freedom are Surge, Sway, Heave, Pitch, Yaw, and Roll. Typically a crane operator will feel a variety of these movements, depending upon the equipment or crane model they are operating. While GlobalSim builds some high-end 6 DOF motion systems, many of the systems (particularly for port cranes and military cranes) only feature a 3 DOF system that incorporates the exact type of motion the operator feels as they operate the crane.

For example, a Ship-to-Shore crane often creates a sideways “sway” motion during its operation. The cabin also moves forward, creating a “surge” motion. Finally, when a container is picked up, the operator will feel the cabin “pitch”. It is important that a trainee practice on a simulator that induces all three of these motion cues. If a trainee were to feel insufficient movement or motion in the wrong axis, this may provide negative training value because the student’s eye conflicts with what they feel. “That’s why we prefer a full-motion cabin,” says Ball. “Motion is an extremely important element in training. The seat-based motion systems just can’t compare to an enclosed cabin with a proper full motion system. The feel is so much more accurate, and it provides for a more immersive experience for the student operator.”

[embedyt] https://www.youtube.com/watch?v=pHjCxNACwS8[/embedyt]Conclusion

Because motion-based simulators are so effective in training crane operators in an immersive environment that closely resembles real-world conditions, companies that train new operators with GlobalSim’s state-of-the-art systems are better prepared, more accurate, and more confident. The realistic training experience allows practice through scenarios that are impossible to replicate on actual equipment. Companies who are dedicated to providing their students such an immersive training experience are setting their employees and their businesses up for long-term success. And the caliber of their work will improve the entire industry.

Contact GlobalSim today to learn more about motion-systems in a simulated environment.